HOW TO MAKE A 3' QUARTER PIPE

Here's another quick and easy to build 3' tall, 4' wide quarter which was requested by a reader. The transition is a little less steep at a 6'-0 radius than the "micro" quarter.

As with all structures here on DIYskate, you can build this quarter any size you want. But for the material list to be accurate you will need to follow the plans as listed below.

WHERE TO GET SUPPLIES

The wood and hardware can be found at most home improvement stores. Sometimes you can find the steel there as well, I know my local Home Depot carries the coping and threshold material.

If not, you can search the internet for steel fabricators or salvage steel. Personally, I've begun buying my steel from MetalsDepot.com because of their very quick shipping and good prices. I'm not affiliated with them in any way, I just like them and their product.

If this ramp is going to stay outside, it needs to be protected from the elements. A good place to start is with pressure treated lumber, paint and a tarp. You may want to invest in a composite material for the surface too. Such as Skate Lite or Ramp Armor.

Be extra careful when working with treated lumber though, the chemicals used to treat the wood contain a poisonous pesticide.

BUILD IT

Gather all your materials. Start with the 2x4's. Cut 13 pieces at 3'-10 1/2 in length (you will get 2 out of each 8' long 2x4). Set them aside. Below is a cut list referencing what else you will need and it's size.

PLYWOOD LAYOUT

Above you will find a plywood layout illustration, it depicts the sides and deck of the quarter pipe being cut from a single sheet of 3/4" plywood.

.gif)

DRAWING THE TRANSITION

Theres a few different ways to do this, I'm going to explain it the way I do it. Grab an 8" long 2x4. On one end, drill a hole the diameter of a pencil (about 3/8"). Then measure from the hole you just drilled, out the distance of the transition radius. In this case, 6'-0. Place a screw there but don't go all the way through the 2x4 yet.

ake your 3/4" plywood and lay it on a fairly level surface. Grab another sheet of plywood, your 3/8" sheet should do, you might have to place some scrap wood under it to bring it up to the level of the 3/4". Place it next to the 3/4" plywood, long end to long end, touching.

With the 2x4 you made earlier, screw the screw into the 3/8" plywood where shown above. Now you want to draw a radius using the 2x4 to guide your pencil until you have the transition radius clearly visible on the 3/4" sheet of plywood. Once done, measure up 2'-11 1/4 and out 5'-10 3/4 from the bottom left side to complete drawing the transition.

CUT THE TRANSITION

Very carefully cut on the lines you drew for the transition. The top layer for the deck comes out of this 3/4" ply also, so try not to get too crazy with the jig saw.

Once cut, use this transition as your template to trace onto the plywood and cut out the other side.

FRAMING THE BOTTOM

Your done with the hardest part, now it's time to frame the quarter pipe. Start by attaching the bottom and top 2x4's as shown.

FRAMING THE CENTER

Take the remaining 2x4's and frame the deck and riding surface portion by placing the 2x4's 8" on center except where noted.

BUYING THE COPING

To find the steel, look up "steel yards", "structural steel" or "steel fabricators" and so on in the phone book.

The actual size of the steel pipe that you are looking for is 2 3/8" (60.33mm) outside diameter. With a wall thickness of 7/32". This pipe is known by steel shops as...

- 2" OD, Schedule 80, black steel pipe

Some steel shops are picky about what it's called so use the above name if they seem confused.

You can also use schedule 40 steel pipe (5/32" wall) as it is cheaper and lighter, but it may become dented. Schedule 80 pipe on the other hand will not dent under normal skateboarding use.

Do not use PVC pipe (plastic) or electrical conduit, if you want it to last.

DRILLING THE COPING

There are more than a few ways to attach the coping to the quarter pipe. In my opinion, screws are the only way. Although I came across another method a while back where you can attach the coping with hook bolts (clothesline bolts) that looks promising.

I have still never used this method but I'm intrested in trying it out. More on that later. For now we're using screws.

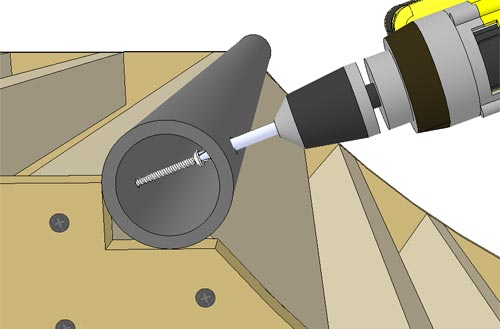

Drill a 3/8" hole on the outside of the steel coping. Now drill a 3/16" hole on the inside of the coping making sure they line up.

ATTACH THE COPING

Once drilled, place the coping in the notch you cut out earlier. By feeding a screw through the outside 3/8" hole, place it into the 3/16" inner hole. This can be tricky but with a little patience you'll get it.

With a drill or screwdriver, screw it down and move on to the next pre drilled hole. You should have a screw on each end and one in the middle.

By the way, don't worry about the holes interfering with your skating. You'll never feel them, guaranteed (unless they are larger than 3/8").

ATTACHING THE DECK

Take the remaining 3/4" plywood, cut two pieces at 4' by 11 1/4" and screw them to the top of the ramp putting screws about a foot apart in each 2x4.

COVERING THE RAMP

TAt this time get your 3/8" plywood and cut out a piece 5'-6 by 4'-0. Start at the top and place the screws about a foot apart working your way down the ramp. Make sure you hit the studs when your attaching it. You can use a chalkline or a 2x4 to mark a line across the ramp to be sure.

Once the bottom layer is attached, cut another piece of 3/8" plywood to 5'-9 by 4'-0. This will be your second layer and you will want to attach it in the same way as the first making sure you hit the studs and the screws about 8" apart.

ATTACHING THE MASONITE

With both of the 3/8" sheets fully screwed down, cut a piece of masonite 4'-6 by 4'-0 and attach it the same way you did the last two layers. Only this time you will want to countersink your screws a little bit using a countersink bit or a 3/8" drill bit. This allows the surface to be as smooth as possible and keeps your body from being ripped to shreds during a fall.

With the masonite on, you will be able to check the coping placement. I prefer the coping to stick out 3/8". If you want to change it, remove the coping and place wood shims where it meets the 2x4's.

ATTACHING THE THRESHOLD

If constructed properly, you should have about 1'-6 between the masonite and the ground. This is where you place the 4' x 1'-6, 3/16" thick sheet metal or 1/4" plastic.

Drill a 3/16" hole about 2 inches in from each end on both sides and one in the middle. After the holes are drilled, countersink each by using the 3/8" drill bit to drill down just enough so the screw heads are flush.

The steel threshold is also availabe at steel fabrication shops. You may be able to find the steel at home improvement stores too. They don't have the best selection, but it might be enough to get you by.

SKATE IT

There ya go, that's all you need to know to make a 3' tall, 4' wide quarter. If you are going to leave this ramp outside, you'll need to seal it with paint or watersealer and cover it with a tarp.

Good luck and have fun... Thanks to Zack for the ramp suggestion.